Buck, Seifert & Jost, Inc. continued its service to United Water New Jersey (UWNJ) for improvements at the Haworth Water Treatment Plant in 2007 through 2011, having designed and provided construction services for the original plant in the 1960s, and expanded plant in the 1980s. Working together with UWNJ and Camp, Dresser & McKee (CDM) Inc., BS&J provided consulting engineering services as part of an engineer, procure, construct (EPC) design-build contract between UWNJ and CDM. The improvements included the addition of Dissolved Air Flotation (DAF),

the replacement of the 1980s ozone system with a new Ozone System, the conversion of existing basins for disinfection, and the addition of new Residuals Handling facilities. The DAF has enhanced water treatment and significantly extended filter run times. The new Ozone System employs the latest ozone generation and contact technologies with greater efficiency. The disinfection basins increased the contact time with sodium hypochlorite and reduced the required sodium hypochlorite dose. The clarification and reuse of filter backwash water in the new Residuals Handling System conserves water for treatment and distribution.

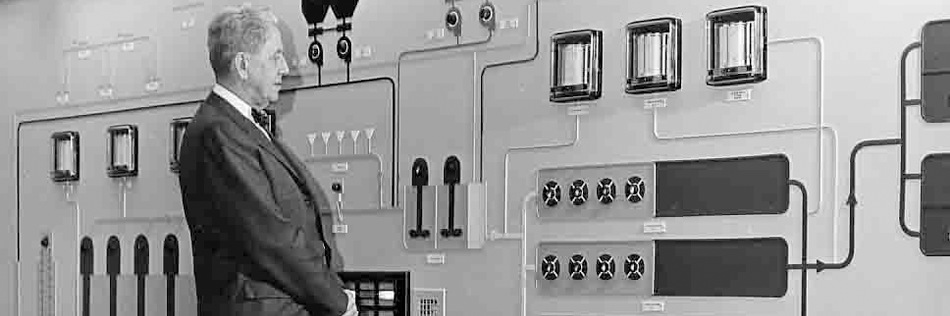

During this same period, BS&J designed and provided construction services for the replacement of the primary Motor Control Center (MCC) for the Plant. The MCC was original to the 1960s plant construction. Replacing the MCC was likened by some to open heart surgery and required careful planning and methodical construction. This challenging assignment was successfully completed by Mehl Electric Company, Inc. and J. Fletcher Creamer & Son, Inc. working closely together with UWNJ engineering and operations staff, and BS&J.